316th Civil Engineer Squadron ensures airfield safety with decennial arresting system overhaul

The BAK-12 system is an emergency braking mechanism designed to attach to the arresting hooks affixed to an aircraft's tail. The system rapidly decelerates aircraft during short-distance or emergency landings, facilitating a safe and controlled arrival.

“The job of the aircraft arresting system is to save the lives of pilots, radar intercept officers or other passengers that may be on the plane,” said Jonathan Rajski, a 316th CES power production and aircraft arresting systems mechanic. “It functions through a mechanical system that hydraulically slows down the aircraft.”

The system is overhauled every 10 years to ensure airfield safety and readiness, while also allowing the 316th CES to perform maintenance inspections.

“Think of the system as if you were putting your thumb over a garden hose that is running. The more you put your thumb over the water, the farther the water sprays, hence more pressure,” Rajski said. “It is the same principle used here. The more the plane tries to go farther down the runway, the more the ‘thumb,’ in this case a needle valve, closes into the oncoming hydraulic fluid building pressure, bringing the aircraft to a stop.”

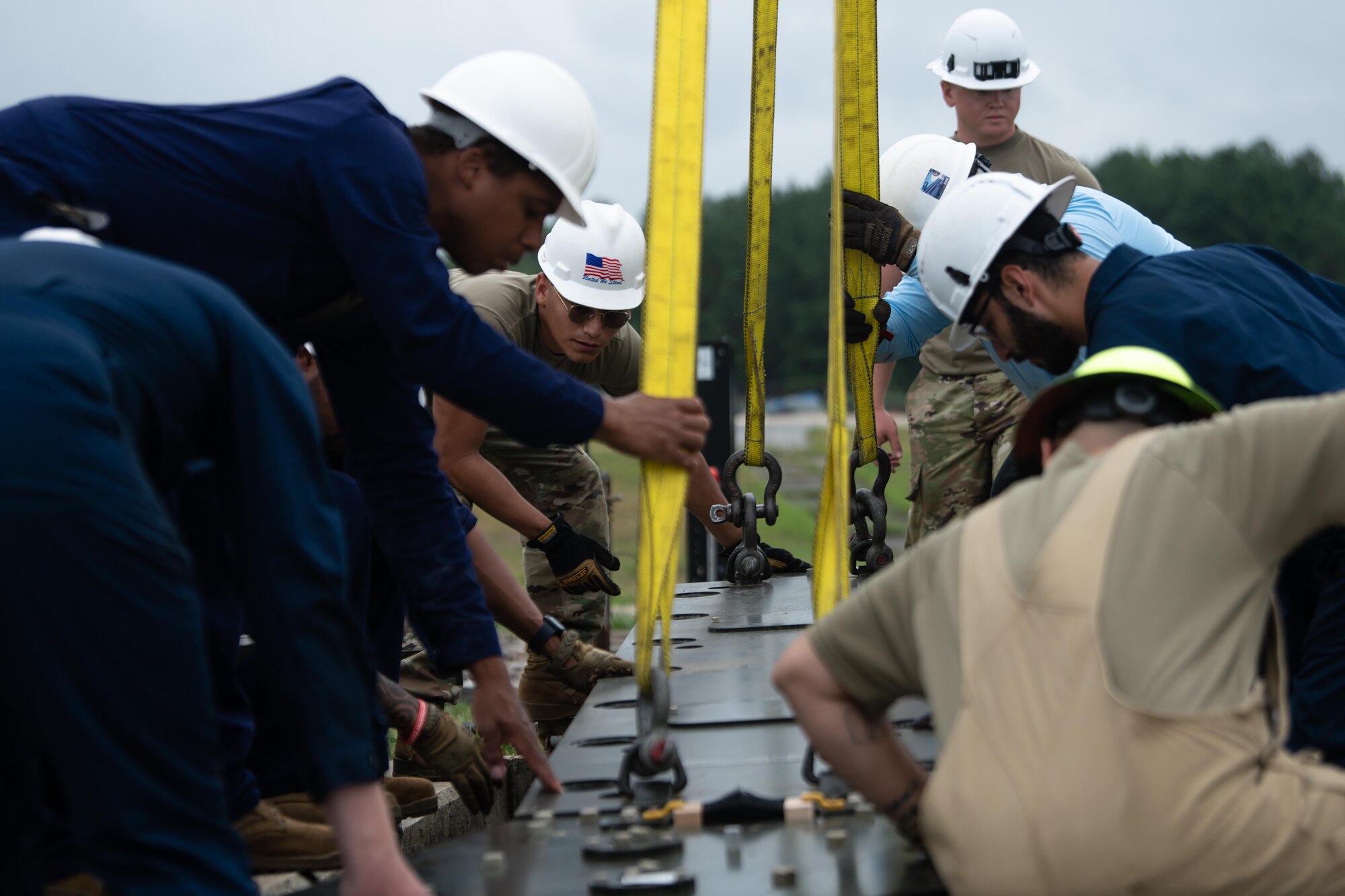

Given the variety of aircraft supported by Andrews, the BAK-12 system is a crucial element in ensuring the safety of the pilots and their equipment. The 316th CES made the overhaul a top priority, dedicating resources and manpower to complete the project. Since the BAK-12 system is replaced every 10 years, Airmen gained valuable experience and insight while working on the project.

“Some people never get an opportunity like this,” said Staff Sgt. Ember Houle, a 316th CES electrical power production shop technician. “It’s something that happens every 10 years, so, some Airmen never get to be a part of a project like this. I feel thankful for the experience and all of our younger, newer Airmen to be able to be a part of this as well.”

After two weeks of the overhaul process, the newly installed BAK-12 system underwent a live test on Aug. 13. The test involved an F-16 Fighting Falcon aircraft assigned to the 113th Wing conducting a high-speed taxi. The aircraft successfully caught the braking system and came to a halt, marking the end of the decennial installation process for the 316th CES Airmen and ensuring continued aircrew and passenger safety at America’s Airfield.